Custompulper System

Custompulper System

The EDGE Custompulpers are designed to meet specific mill requirements and conditions. We offer 8 pre-engineered tub sizes, each available in batch, batch extraction, continuous and continuous extraction configurations. Our 32 basic designs are further customized for height, tonnage, horse power and material of construction. Tubs are constructed of steel, stainless steel or steel with a stainless steel lining.

The design of your Custompulper will be based on your system requirements, the capacity you wish to pulp and the type of furnish you are planning to use. Our experienced design engineers will work with you to make certain that you have the right equipment for you specific need, whether it's a Custompulper or a complete system.

|

|

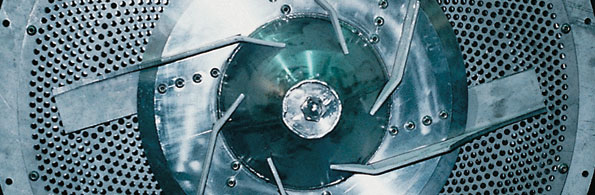

Pulping Action

The Angulobe tub design is a unique feature of the EDGE Custompulper. The sides are formed into four lobes, each with four angular plates tapering form top to bottom. The design is a cloverleaf effect which enables acceleration/deceleration of the furnish and four distinct folds down into the rotor's vortex. Solids separation occurs naturally with areas of low velocity and points of high agitation giving maximum fiber to fiber interaction. Shorter cycle times, minimum fiber damage and ease of contamination removal are the advantages of this superior construction.

|